Per CDC’s latest recommendations, “soft and porous materials that are not frequently touched should only be cleaned or laundered, following the directions on the item’s label, using the warmest appropriate water setting.” More specifically for clothing, towels, linens, and other items’ laundry, you should follow the best practices including wearing disposable gloves, not shaking dirty laundry, using the warmest appropriate water setting, etc (see CDC guideline). You can access the full reopening guidance for cleaning and disinfecting from CDC here.

Textile Hygiene and Infection Control

It can be hard to always conduct the recommended practices yourselves when it comes to laundry. A professional launder like CLEAN offers substantial benefits to removing contaminants compared to home laundry because:

- The wash process is optimized around four parameters: time, temperature, mechanical action, chemical action

- Water throughout the process adds dilution effect

- Machine action and textiles rubbing against each other adds mechanical action to remove contaminants

- Detergent loosens contaminants, helps to remove them from the textile, suspend them in wash water solution, and sends them down the drain

- Oxidation process helps to remove contaminants, decolor stains, and some oxidizers aid in microorganism deactivation

Our HACCP and HLAC certified facility also ensure we follow the industry standards and achieve the best practices in plant cleanliness and process controls.

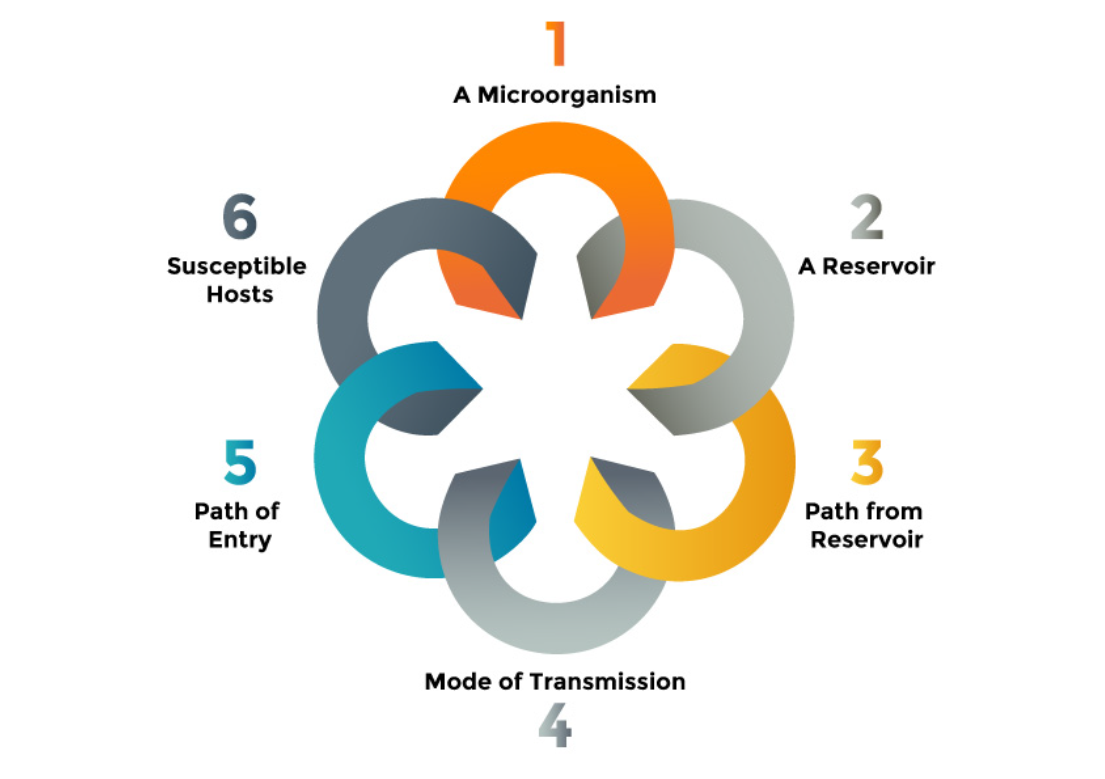

Since the Covid-19 outbreak, CLEAN has been monitoring the situation closely and adopted safety precaution measures to be uniquely positioned to control critical areas to break the chain of infection:

BREAK THE CHAIN FROM 3 to 4

- Properly collect, bag, and sort soiled linens utilizing universal precautions

BREAK THE CHAIN FROM 4 to 5

- Employee wear proper PPE including gloves, barrier coat, face masks and safety glasses;

- Properly store and cover clean textiles;

- Work stations equipped with sanitizers and wipes/towels to disinfect hard surfaces;

- Employees are required to wash hands frequently and not touch their nose, mouth, eyes, or face

- Process control to manage the critical control areas

BREAK THE CHAIN FROM 5 to 6

- Wash process optimized around time, temperature, mechanical action, chemical action to launder contaminated textiles

- Employees working from home to reduce the spread

EPA-registered Antimicrobial Intervention

CLEAN launders our garments for the healthcare and food service industries using AdvaCare™, which is an EPA-registered laundry disinfectant (EPA no. 1677-193) with eleven kill claims against eleven microorganisms:

- Staphylococcus aureus

- Klebsiella pneumoniae

- Pseudomonas aeruginosa

- Acinetobacter baumannii

- Escherichia coli 0157:H7

- Listeria monocytogenes

- Methicillin – Resistant Staphylococcus aureus (MRSA)

- Community-associated Methicillin-Resistant Staphylococcus aureus (CA-MRSA)

- Salmonella enterica

- HIV-1 (AIDS) Virus

- Carbapenem – resistant Klebsiella Pneumoniae (KPC)

- Enterococcus faecalis – VRE

- Clostridium difficile

AdvaCare Disinfectant outperforms chlorine and peroxide for disinfecting, whiteness, extending linen life, sustainability and overall effectiveness.

The CLEAN Difference

As one of the independent, family-owned industrial launders, CLEAN sets ourselves apart by being different:

- RFID empowered tracking system guarantees each of your garments are tracked through the whole facility and are delivered accurately;

- Route sales representative (RSR) check in with you on site and proactively adjust to any inventory changes;

- All dirty items will be exchanged for a clean and proper amount of inventories;

- Delivery points will be cleaned and organized and an RSR will review the delivery and invoice with you prior to obtaining invoice approval;

- Launder garments through ISO environmentally certified washing process and facility that minimizes the impact on the environment;

We understand the challenges at this pivotal moment and the importance of flexibility to cater to customers’ needs. Contact us and get a free cost analysis today; we are more than willing to prepare you better for your business.

1-800-GO-CLEAN

1-800-GO-CLEAN